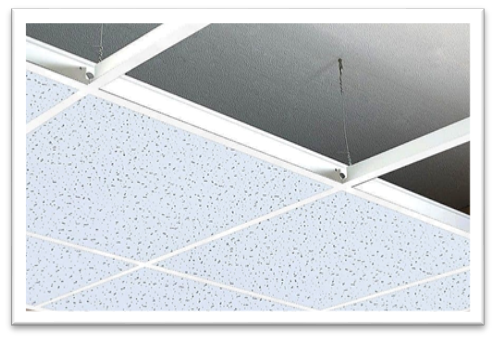

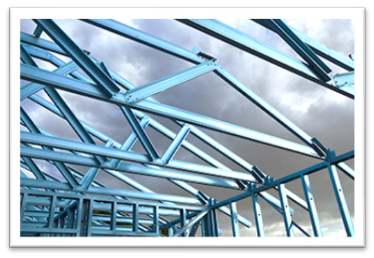

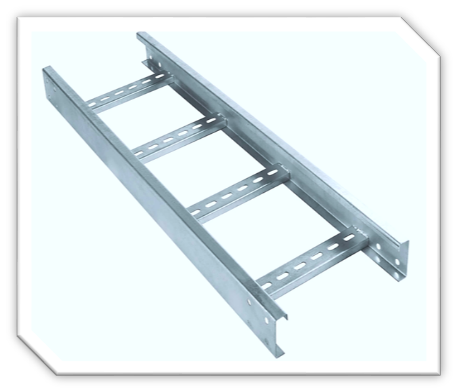

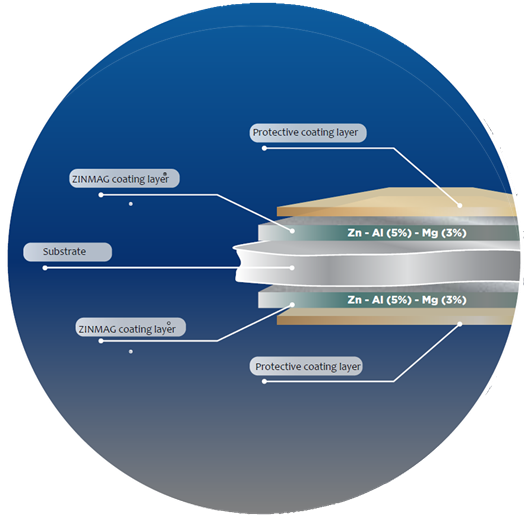

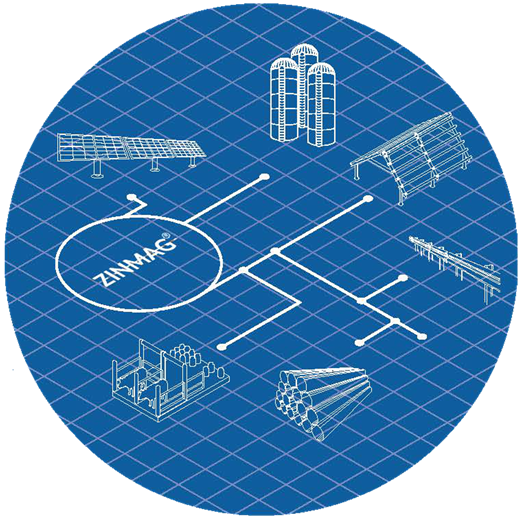

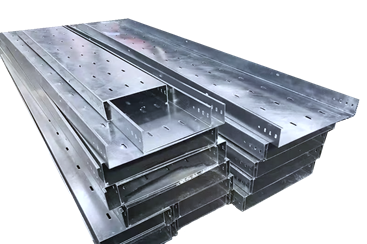

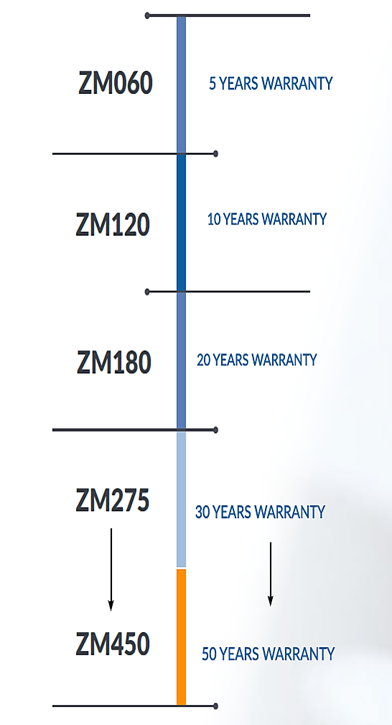

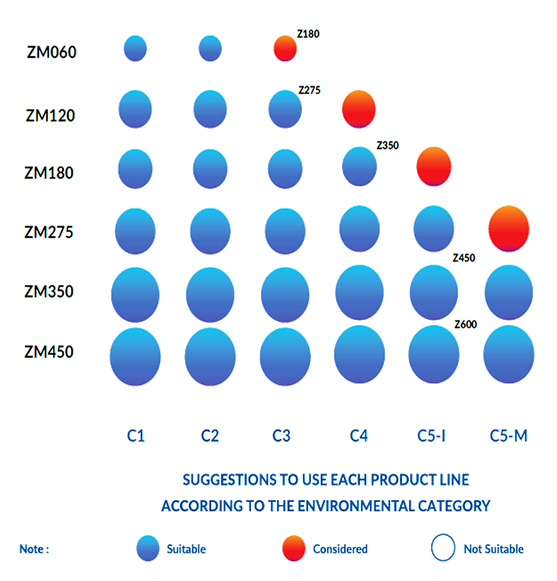

SAN introduces ZINMAG which is also called as SUPERDYMA which is a high corrosion–resistant coated steel with a special alloy composition. ZINMAG (SUPERDYMA) with its unique coating layer of Zinc, 5% Aluminum, and 3% Magnesium coating provides a breakthrough solution in surface corrosion and metal cutting-edge protection, making it possible to be applied even in the most severe environments (C5) such as livestock, chemicals, and marine areas. ZINMAG (SUPERDYMA) can switch many traditional steel and metal materials in various applications in our life at a greatly competitive cost.For More information and usage on ZINMAG (SUPERDYMA), please do contact SAN office personal.

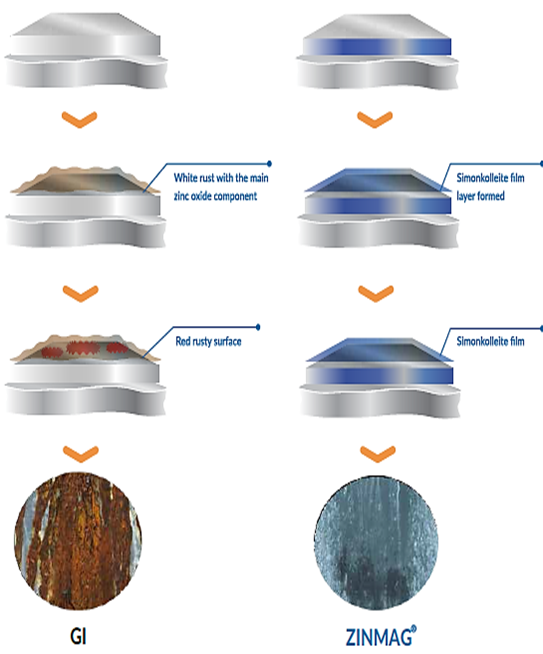

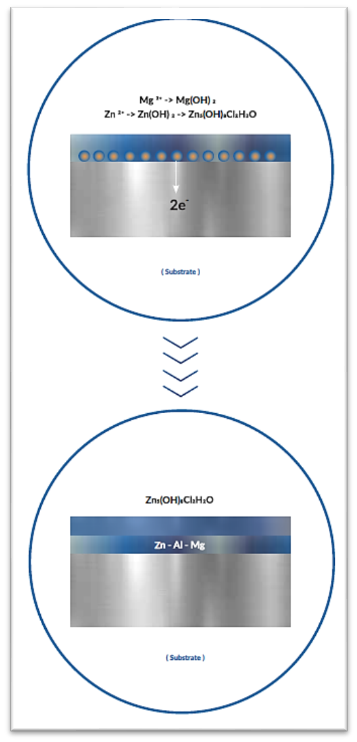

The magnesium in the ZINMAG (SUPERDYMA) coating is a catalyst that will accelerate the formation of a highly resistant crystalline film / a dense corrosion product which is extremely stable and officially called Simonkolleite [Zn5(OH)8Cl2.H2O] (SKT). When Simonkolleite is formed, it gradually moves outward to seal the entire steel base surface and prevent it from corrosive environmental substances and plays an important role as a corrosion inhibitor for the base metal.

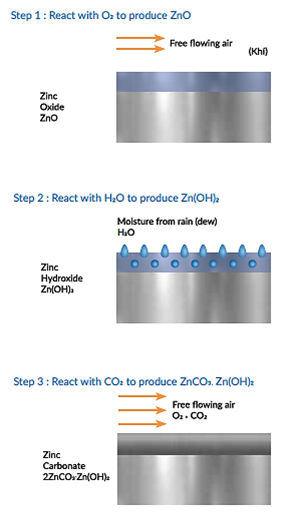

Because of the spongy nature, the corrosive substances continue to break into the zinc oxide layer to cause red rust occurrence.

SKT had a close chemical formula that can prevent the penetration of corrosive elements.

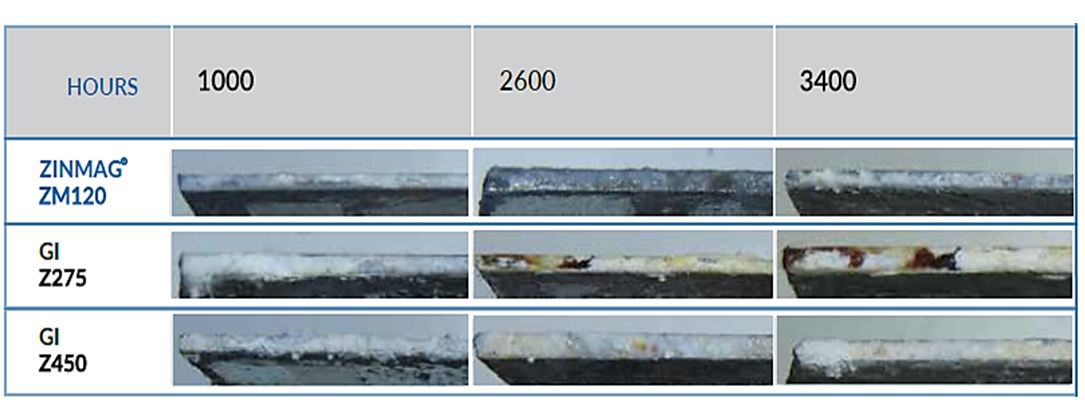

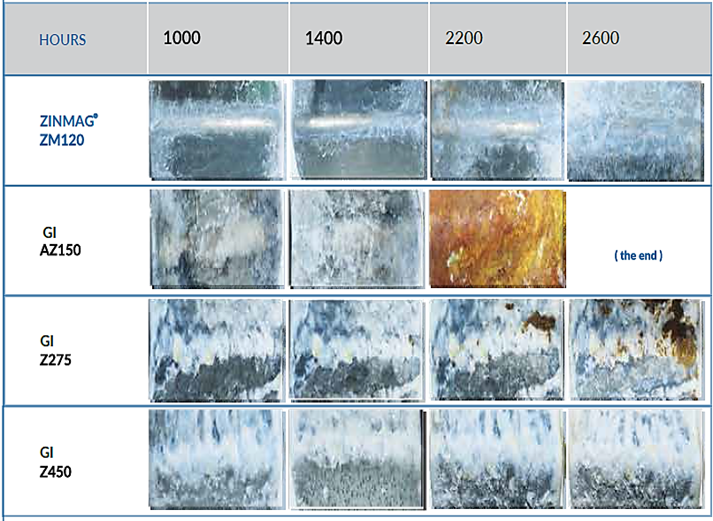

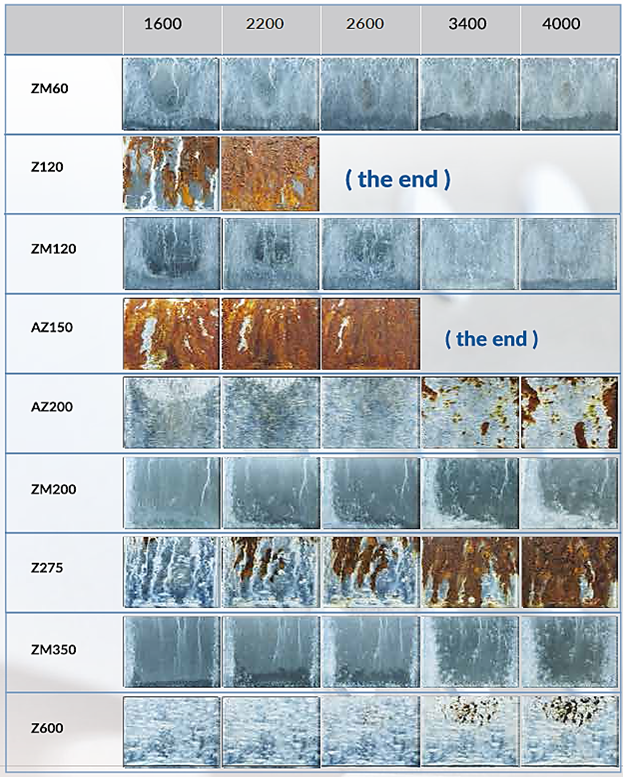

The anti-rust ability on the cutting edge of ZINMAG (SUPERDYMA) is extremely greater than Galvanized with the equivalent coating, in which, after 3400 hours testing, ZINMAG (SUPERDYMA)'s cutting edge is entirely unchanged, proving that SKT's formability and self-filling ability are significantly effective while the GI cut-edge is severely rusted.

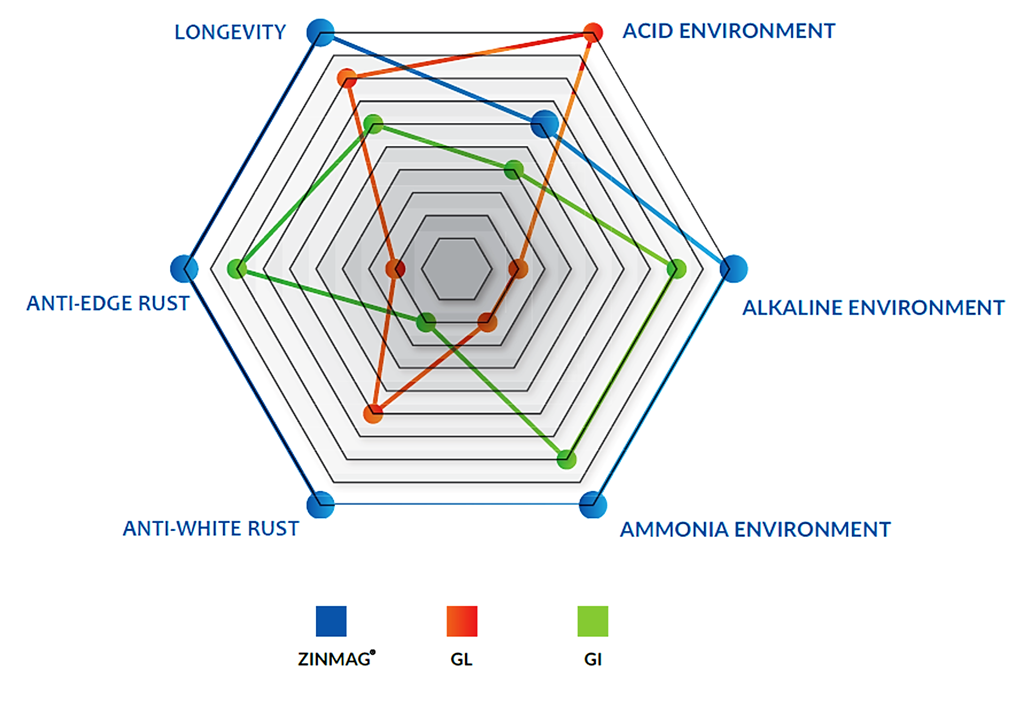

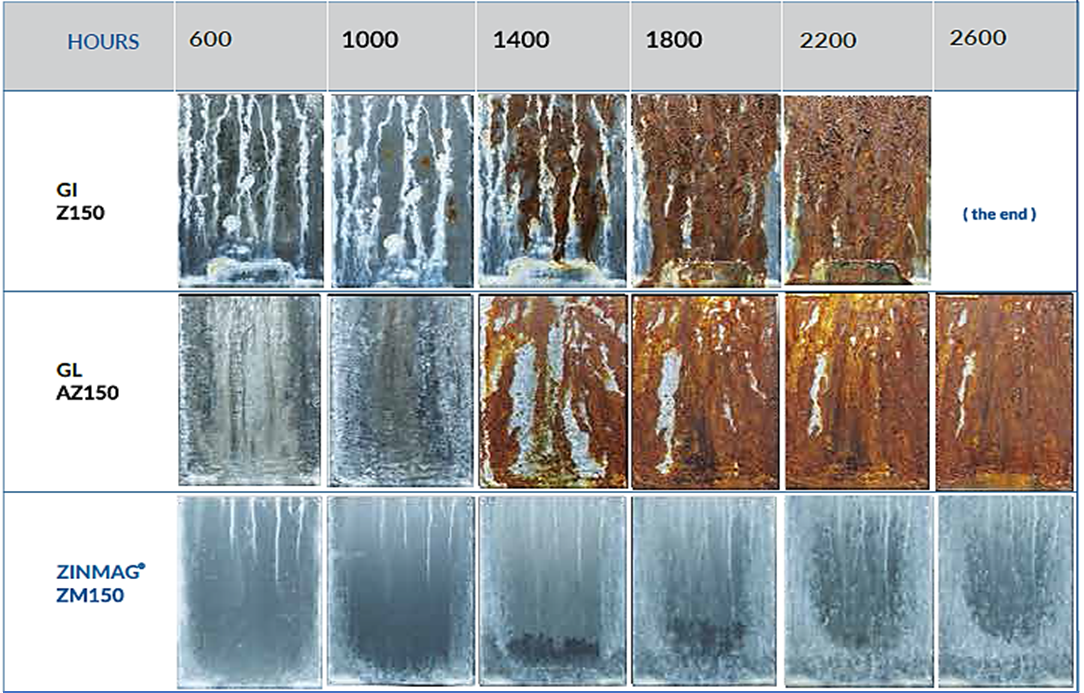

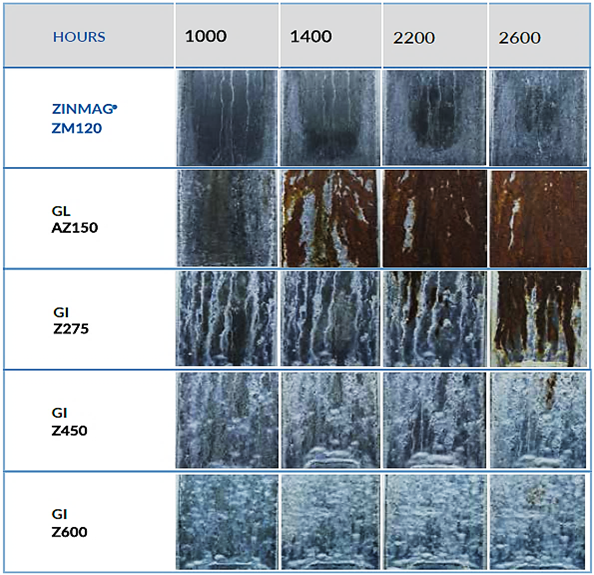

ZINMAG (SUPERDYMA)'S corrosive resistance ability on the flat surface is much better than GL and GI. Especially, by this test, it can be clearly shown that it is 5 times higher than normal GI.

The corrosion resistance on flat surface of ZINMAG (SUPERDYMA) is remarkably superior compared to normal GI, GL

In relation to the above tests, ZINMAG (SUPERDYMA)'s anti-rust is completely much better than normal GL and GI. This test has surely demonstrated that ZINMAG (SUPERDYMA) is a breakthrough corrosion-resistance in the coated

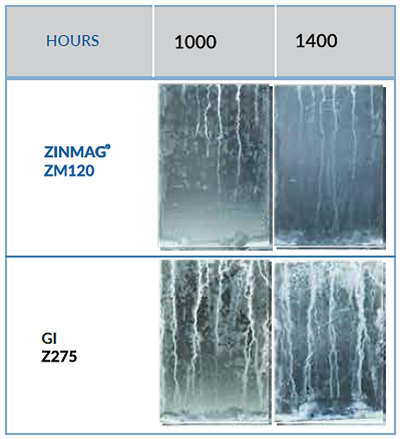

ZINMAG (SUPERDYMA) white rust resistance ability is severely higher than GI. It is clearly seen that the SKT layer formed in the inhibiting the white rust formation process of zinc with Oxygen, Carbon Dioxide and water steam to create a white layer which is resulted by a salt mixture of Carbonated (ZnCo3) and Hydroxide(Zn(OH)2).

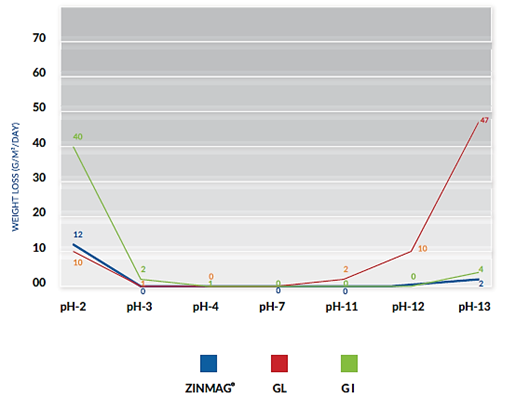

Comparing the weight before and after soaking GL, GI and ZINMAG (SUPERDYMA) in Na2SO4 solution at 30⁰C after 24hr Potential of hydrogen (PH) concentration increases progressively from 2 to 13 by adding H2SO4 or NaOH solution.

Comparing the weight before and after soaking GL, GI and ZINMAG (SUPERDYMA) in Na2SO4 solution at 30 degree Celsius after 24h; Potential of hydrogen (PH) concentration increases progressively from 2 to 13 by adding H2so4 or NaOH solution.

In acidic environment, GI is corroded quite quickly white GL and ZINMAG (SUPERDYMA) are equivalently slower. However, in alkaline environment, ZINMAG (SUPERDYMA) corrosion is 50% lower than GI and much better than GL.

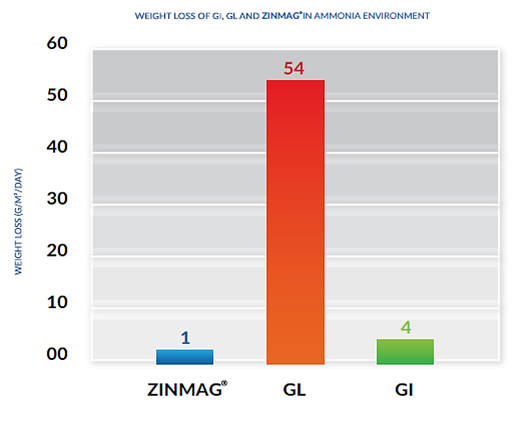

In the ammonia (breeding) environment, the corrosion resistance of ZINMAG (SUPERDYMA) is 4 times stronger than that of normal GI, and it is recommended that GL should not be used in the ammonia environment due to poor corrosion resistance

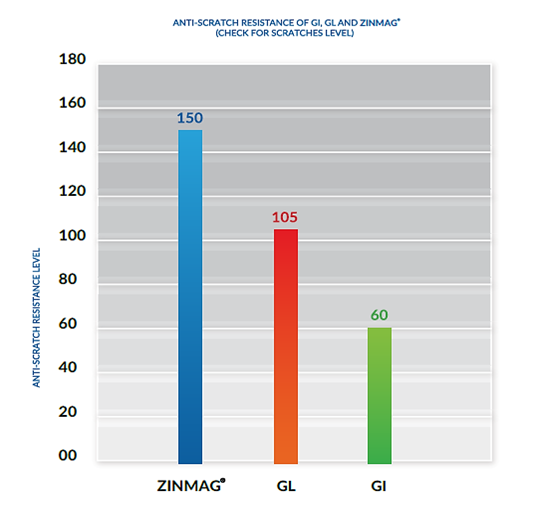

ZINMAG (SUPERDYMA) has a harder coating layer than GI and GL. As a result, ZINMAG (SUPERDYMA) offers better scratch resistance to reduce abrasion caused by processing and forming, transportation, storage or erection, such as fixing under the ground.

In the ammonia (breeding) environment, the corrosion resistance of ZINMAG (SUPERDYMA) is 4 times stronger than that of normal GI, and it is recommended that GL should not be used in the ammonia environment due to poor corrosion resistance.

ZINMAG (SUPERDYMA) is a highly corrosion-resistance alloy steel coil that meets both price and quality criteria.