Key Aspects of Laser Cutting Services:

1.Types of Laser Cutting:

- CO2 Laser Cutting: Ideal for non-metal materials like wood, acrylic, plastic, fabric, and some metals.

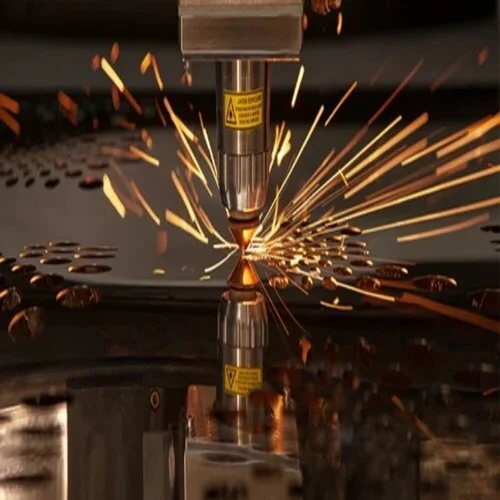

- Fiber Laser Cutting: Highly effective for cutting metals such as steel, aluminum, brass, and copper.

- Nd/Nd Lasers: Used for applications requiring high power and precision, often in the medical and electronics industries.

2.Materials:

- Metals: Steel, stainless steel, aluminum, brass, copper, and more.

- Non-metals: Wood, acrylic, plastic, leather, fabric, glass, and ceramics

- Composites: Various composite materials used in specialized applications.

3.Applications:

- Industrial Manufacturing: Creating parts and components for machinery, automotive, aerospace, and electronics.

- Construction: Cutting materials for building and architectural projects.

- Art and Design: Crafting intricate designs for art pieces, jewelry, signage, and custom decor.

- Medical Devices: Precision cutting for surgical instruments and medical devices.

- Electronics: Cutting and engraving components for electronic devices and circuit boards.

4.Process:

- Design Preparation: Using CAD (Computer-Aided Design) software to create precise design files.

-

Material Selection: Choosing the appropriate material based on the project requirements.

- Laser Setup: Configuring the laser cutter with the correct settings for the material and design.

-

Cutting/Engraving: Executing the laser cutting or engraving process with precision.

- Finishing: Post-processing tasks such as cleaning, assembly, and quality inspection.

5.Benefits:

-

Precision and Accuracy: Achieving intricate and complex designs with high precision.

- Versatility: Capable of cutting a wide range of materials with different thicknesses.

- Efficiency: Fast turnaround times due to the speed and automation of laser cutting.

- Quality: Producing clean cuts with minimal material waste and deformation.

-

Customization: Offering tailored solutions for unique and specific project needs.

6.Finding a Provider:

- Experience and Expertise: Look for providers with a strong background in laser cutting and a diverse portfolio of projects.

- Technology and Equipment: Ensure they use advanced and well-maintained laser cutting equipment.

-

Customer Reviews and References: Check reviews and ask for references to gauge the provider’s reliability and quality of service.

- Capabilities and Services: Verify that they can handle the specific materials and designs you require.

-

Support and Communication: Good communication and customer support are essential for a smooth process and satisfactory results.

Conclusion

Laser cutting services offer a versatile and precise solution for a wide range of applications. By selecting a reputable provider with the right expertise and technology, you can achieve high-quality results tailored to your specific needs. Whether for industrial, commercial, or artistic purposes, laser cutting can enhance efficiency, accuracy, and creativity in your projects.