Laser welding services use high-powered lasers to join metal or thermoplastic parts with

precision and strength. This process is essential in industries where strong, precise, and clean

welds are required, such as automotive, aerospace, medical devices, and electronics.

Key Aspects of Laser Welding Services:

1.Types of Laser Welding:

- Conduction Welding: Uses low power density lasers to melt the material's surface, ideal for thin materials.

- Keyhole Welding: Utilizes high power density lasers to create deep, narrow welds by vaporizing the material, forming a "keyhole."

- Hybrid Laser Welding: Combines laser welding with another welding process (e.g., MIG or TIG) to enhance the weld quality and speed.

2.Materials:

- Metals: Steel, stainless steel, aluminum, titanium, nickel alloys, and more.

- Thermoplastics: Certain plastics that can be melted and re-solidified without degradation.

3.Applications:

- Automotive: Welding body panels, transmission components, and exhaust systems.

- Aerospace: Joining critical structural components and intricate parts.

- Medical Devices: Manufacturing surgical instruments, implants, and medical equipment.

- Electronics: Assembling components like battery packs, sensors, and microelectronics.

4.Process:

- Preparation: Cleaning and aligning the parts to be welded.

- Laser Setup: Configuring the laser parameters (power, speed, focus) based on the material and desired weld characteristics.

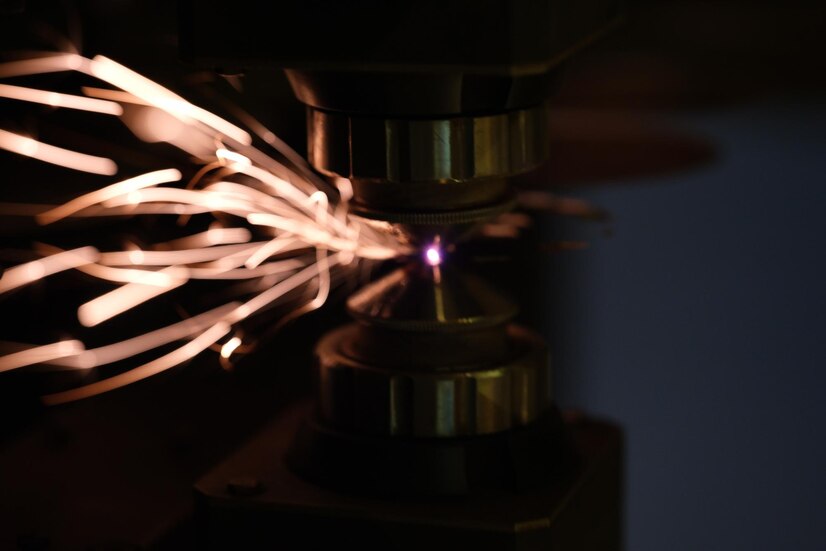

- Welding: The laser beam is directed at the joint area, melting the material to form a weld.

- Cooling and Inspection: Allowing the weld to cool and solidify, followed by inspecting the weld quality using non-destructive testing methods.

5.Benefits:

- Precision: Produces highly accurate and consistent welds.

- Speed: Faster than traditional welding methods, increasing productivity.

- Strength: Creates strong, durable welds with minimal distortion.

- Versatility: Suitable for a wide range of materials and complex geometries.

- Cleanliness: Produces clean welds with minimal spatter and contamination.

6.Finding a Provider:

- Experience and Expertise: Look for providers with extensive experience and specialized knowledge in laser welding.

- Technology and Equipment: Ensure they use advanced laser welding machines and equipment.

- Customer Reviews and References: Check reviews and ask for references to gauge the provider’s reliability and quality of service.

- Capabilities and Services: Verify that they can handle your specific materials, part sizes, and production volumes.

- Support and Communication: Good communication and customer support are essential for a smooth process and satisfactory results.

Conclusion

Laser welding services offer a precise, efficient, and versatile solution for joining metal and thermoplastic parts. By selecting a reputable provider with the right expertise and technology, you can achieve high-quality, strong, and clean welds tailored to your specific needs. Whether for automotive, aerospace, medical, electronics, or other applications, laser welding is fundamental in producing reliable and high-performance assemblies.