29-07-2025

SAN Engineering and Electrical Support can provide durable and corrosion-resistant solutions to any industrial support system. One of our leading products is the Hot Dip Galvanized (HDG) Unistruct Channel, which can be found in virtually every electrical, mechanical, and structural installation. This article will not only talk about what it is and its function, but we'll also describe how we manufacture it with strict adherence to quality control.

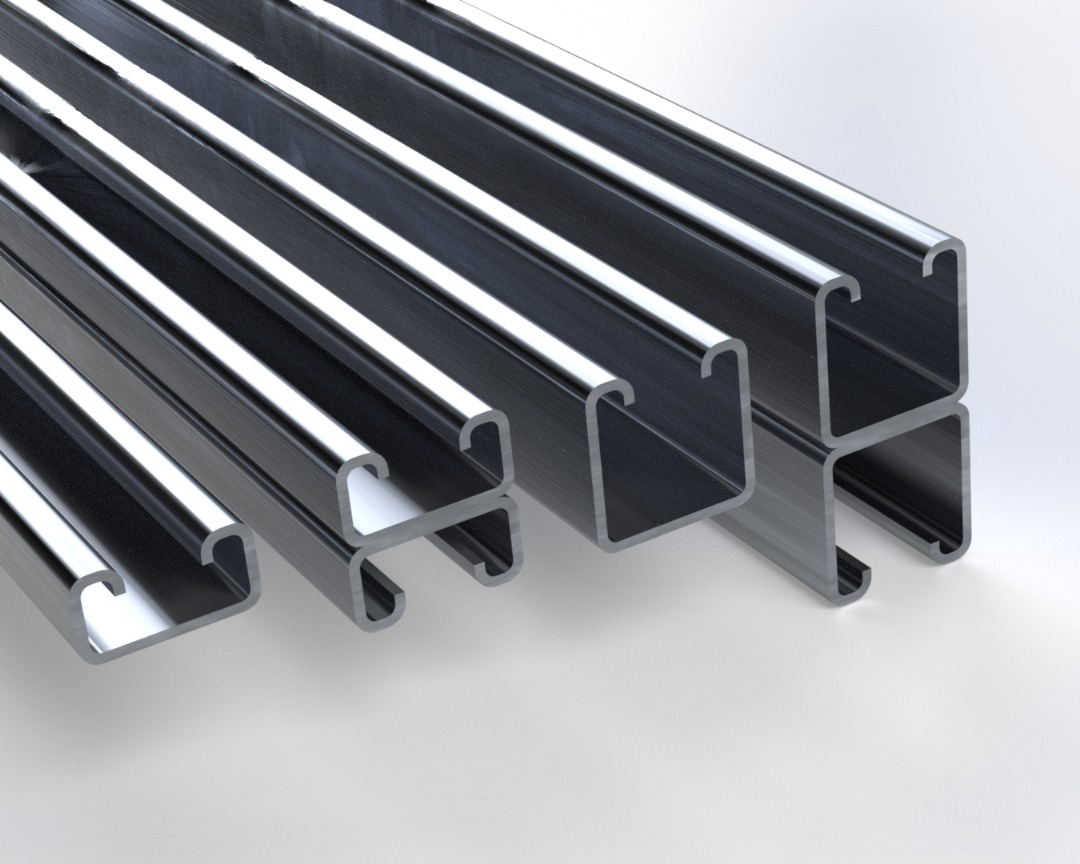

A Hot Dip Galvanized Unistruct Channel is a type of metal framing system made from steel, but is coated in a protective layer of zinc during the hot dip galvanising process. The galvanisation process prevents rust and corrosion and makes the hot dip galvanised channel and framing system appropriate for outdoor and difficult environments.

Unistruct Channel is used in support structures for piping, cable trays, electrical conduits, HVAC systems, and solar panel frameworks to name just a few.

The Unistruct channel system is a modular framing system that supports various loads without the need of welding. The main functions include:

As a modular system with many accessories, it provides flexibility for quick installation and future load expansions.

The Hot Dip Galvanized Unistruct channel manufacturing process is designed to incorporate strength, detail, and corrosion resistance. Below is a detailed walk-through about how we manufacture Unistruct channel at SAN Engineering:

At SAN Engineering, we purchase high-quality mild steel coils that are industry-approved for strength and formability. We also inspect the material to ensure there are no defects and that it is suitable for forming.

The mild steel is fed through a roll-formed machine and profiled to the standard Unistruct channel profile. We then shear the channel to the lengths requested by the customer, or to standard sizes that we normally offer.

Throughout production, each batch and each run of the channel is subject to inspections. The method of manufacture requires inspections to measure dimensional accuracy, straightness, and quality of surface finish. Our QA team ensures all inconsistencies are identified before proceeding to the galvanising stage.

Once the channel is formed, the formed channel is taken to the hot dip galvanising process. To galvanise the channel, the formed Unistruct channel is dropped into a vat of molten zinc. Fully galvanising the channel means that both the inside and outside are coated to prevent corrosion, particularly in marine, industrial, and outdoor applications.

After the galvanising process, each channel is then subject to an additional quality check. The final quality check entails checking for zinc thickness, surface finish and structural integrity, ensuring that the channel complies with ISO and ASTM standards.

Upon confirmation, the channels are packaged to avoid any damage during shipping and transported to clients all over Malaysia and beyond. We offer flexible packaging options as needed by customers.

Contact us to learn more about our products or place an order!