29-07-2025

When you need to secure pipes and conduits in industrial or commercial situations, pipe clamps are essential. SAN Engineering and Electrical Support manufactures long-lasting and precision-engineered pipe clamps in Malaysia for a wide range of industries, including plumbing, HVAC, electrical, and construction.

This article will explain what pipe clamps are, how they are used in the Malaysian industry and a walk-through of our manufacturing process.

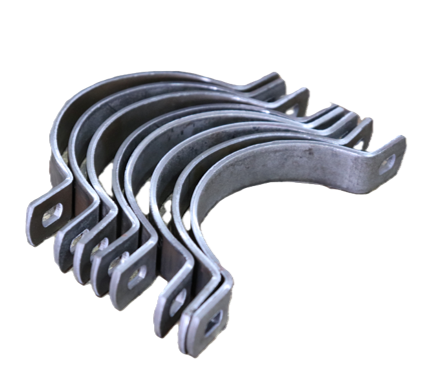

Pipe clamps are a mechanical fastening device used to support, hold and secure pipe, tubing or conduit to a wall, ceiling or structure. Variants of pipe clamps include U-bolts, saddle clamps, split-ring clamps, and cushioned clamps, depending on the size of the pipe and application.

SAN Engineering and Electrical Support manufactures heavy-duty metal pipe clamps which provide better grip, have better vibration resistance, and longevity.

In Malaysia, pipe clamps are widely used across multiple sectors including:

Their key functions include:

We have a strict and systematic way of making sure that every pipe clamp that leaves SAN Engineering and Electrical Support meets industrial-grade standards. Here’s how we manufacture pipe clamps:

We procure high-strength steel sheets or coils to ensure that it meet the required mechanical properties. All raw materials are inspected for thickness, surface finish and overall quality of the steel before moving to the manufacturing stage.

To manufacture pipe clamps, we cut the steel sheets to size and pass them through the following stations and processes:

These processes are all accomplished using high-precision dies and tools to ensure uniformity across all pieces.

TIG (Tungsten Inert Gas) welding is used to join pieces of the clamp together to ensure clean, strong and corrosion-resistant welds, especially relevant to high-pressure and hot applications.

The pipe clamps are galvanised after fabrication. We offer electro-galvanising and hot dip galvanising to meet the application and customer requirements. This step is vital for the long-term durability of a product, particularly in humid or outdoor settings.

Quality Control (QC) inspection is carried out on each pipe clamps to ensure:

Any pipe clamps that support the inspection criteria will proceed to the next stage.

Approved pipe clamps are packed according to customer specifications, ensuring safe handling during transportation. Custom labelling and bulk packaging options are also available.

We deliver across Malaysia and regional markets, providing timely and secure shipments to contractors, M&E consultants, and distributors.

From small-scale residential setups to heavy-duty industrial systems, SAN Engineering and Electrical Support is your go-to partner for reliable pipe clamp solutions in Malaysia.

Contact us today for inquiries or a customised quote.